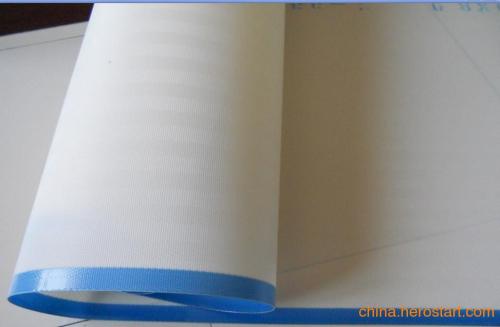

1.Sewage treatment filter belt has high tensile strength, strong anti-please strength, uniform monofilament and flexibility.

2. The filter belt joint is well-made, using imported latex, light and thin, not easy to fall off. The joint steel shovel is relatively thin, strong and wear resistant. The thickness of the interface is even and thin, which is not easy to damage the scraper.

3.The glue used on both sides of the filter belt is imported latex, which is soft and uniform and not easy to fall off.

4.The surface of the filter belt is smooth, the mud cake is easy to peel off, and the filter belt is easy to rinse.

5.The direction of the filter belt is not easily deformed, and it is not arched or wrinkled. Long service life with acid, alkali, abrasion and high temperature resistance (highest temperature resistance 180 ° C, normal temperature).

Different specifications and sizes can be customized to produce.

Products are widely used in urban sewage plants, paper mills, printing and dyeing plants, chemical plants, electroplating plants, pharmaceutical plants, food plants, ceramics factories, mining and other industries sludge dewatering. The sludge dewatering net, also known as the woven mesh belt, is mostly made of stainless steel card joints, and the mesh surface is mostly "human" type. The range is available in a variety of models with different densities and breathability to meet sludge dewatering and pressing in different industries. Product performance: The filter belt joint has high tensile strength and is not easy to be deformed. Easy to install and use. Due to the design structure of the "human" pattern, sludge pressure filtration facilitates the peeling and regeneration of the mud cake and is easy to clean. It has the characteristics of fast water permeability and no muddy. Product advantages: long service life. Price concessions, large quantity favorably. Some special specifications and anti-static products can be customized. Product use: Widely used in urban sewage treatment plants, municipal sewage treatment, environmental sewage treatment, printing and dyeing plants, ceramics factories, paper mills, chemical plants, pharmaceutical plants, tanneries, mineral processing, coal washing, power plant desulfurization, fruit and vegetable pressing and other fields. It is also suitable for solid separation or liquid leaching processes in industrial production.