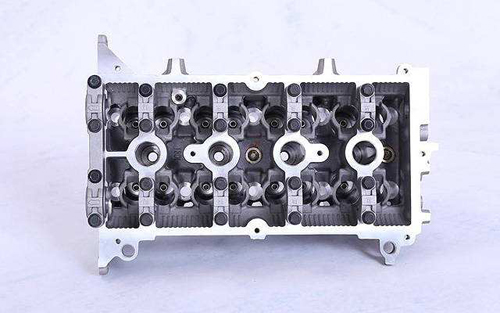

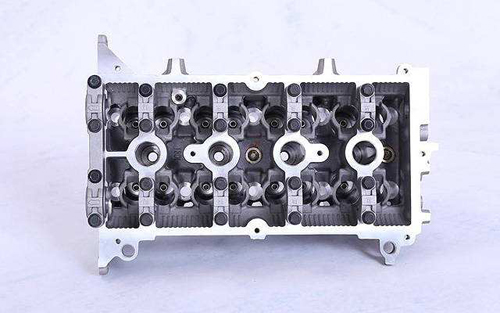

Engine machining center cutting fluid filter cloth (paper), used in automotive engine cover processing centralized filter system filtration vacuum negative pressure filter or self-weight paper tape filter, also applicable to: car engine cover line, gearbox , crankshaft, connecting rod line, engine steering system, transmission system, filter paper for coolant filtration during processing of damping system; filter paper for grinding, grinding and honing machine grinding fluid filtration.

Depending on the product being produced, the filter paper has different filtration accuracy and flux requirements, and the use of filter paper varies. The choice of filter cloth (paper) mainly considers several aspects: 1) the material of the filter cloth; 2) the filtration precision; 3) the strength; 4) the flux; 5) the affinity for the filtered liquid. Its use: As a primary filter in the filtration system, impurities and metal chips are mixed into the coolant during production, which will shorten the service life of the coolant and reduce the working efficiency. At the same time, the cutting fluid is covered by the oil slick for a long time. Breeding anaerobic bacteria, causing the coolant to fail. It is necessary to use filter paper media to filter out the impurities, metal chips and oil in the coolant. In addition, through the filtration of the filter paper, the cold night liquid reaches a certain filtration precision and also reduces the secondary filtration. The pressure of the bag filtration.

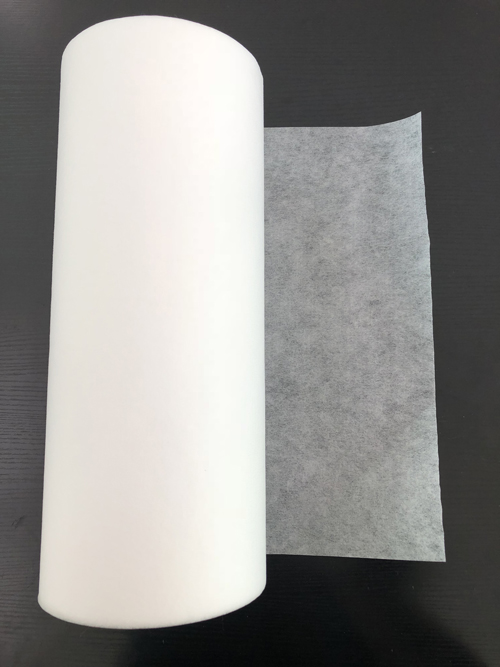

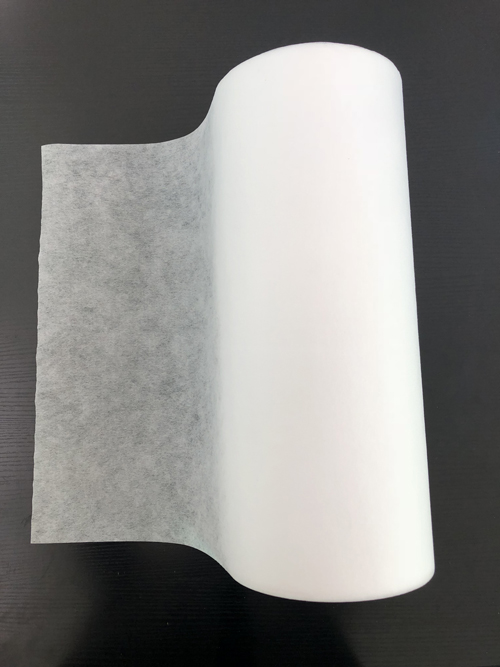

Filter cloth (paper) product features:

Depending on the product being produced, the filter paper has different filtration accuracy and flux requirements, and the use of filter paper varies. The choice of filter cloth (paper) mainly considers several aspects: 1) the material of the filter cloth; 2) the filtration precision; 3) the strength; 4) the flux; 5) the affinity for the filtered liquid. Its characteristics are:

1. The uniformity of the cloth surface is good, using ultra-fine fiber and advanced molding processing technology, the surface pore size distribution is uniform, and the filtration efficiency is high.

2, made of PET or PP fiber, does not contain any curing agent, has no effect on the chemical properties of the dairy liquid.

3, high tensile strength, good immersion resistance, long-term stable use in the range of -40 ° C ~ 120 ° C.

4, good hydrophilic effect, can meet the requirements of large-flux filtration, the same filter accuracy requirements, the use of filter cloth is low.

5, the product coverage is wide, there are a variety of filtration accuracy and flux products to choose from, can meet the different requirements of the filtration precision in the metal processing process.

◎ 相關(guān)客戶常用產(chǎn)品技術(shù)參數(shù):

產(chǎn)品型號 | 克重g/m2 | 厚度mm | 縱向強(qiáng)力N/5cm | 橫向強(qiáng)力N/5cm | 透氣率mm/s | 孔徑分布um | 過濾精度um |

SPS30 | 30 | 0.16 | 83 | 11 | 3983 | 80-110 | 33-45 |

SPS40 | 40 | 0.21 | 88 | 12 | 2698 | 73-99 | 30-41 |

SPS50 | 50 | 0.25 | 130 | 26 | 2384 | 69-87 | 28-36 |

SPS60 | 60 | 0.30 | 167 | 34 | 2276 | 45-59 | 19-25 |

TB4060 | 60 | 0.19 | 70 | 48 | 2569 | 38-43 | 16-18 |

TB3360 | 60 | 0.27 | 160 | 179 | 2004 | 35-45 | 15-19 |

TB4080 | 80 | 0.27 | 102 | 73 | 2286 | 32-40 | 14-17 |

TB3380 | 80 | 0.36 | 315 | 153 | 1383 | 30-38 | 13-16 |